MEMS Deformable Mirrors:

Architecture Description

The Boston Micromachines design for MEMS deformable mirrors is simple in concept but powerful in its capabilities.

An actuator array is built upon a cartesian layout of electrodes. The supported mirror facesheet moves without strong inter-actuator coupling enabling better control compared to the competition. In addition, the architecture of MEMS deformable mirrors enables the fastest response time of any deformable mirror today and the precision is only limited by the electronics. Our standard drivers enable 14 bit control over the full range giving our deformable mirrors an unmatched level of precision out of the box. If more accuracy is desired, increased resolution is available.

Finally, the scalable fabrication process allows us to create multiple configurations in large quantities, enabling lower cost at high volumes. Scroll down for more information about the array of sizes available when selecting BMC deformable mirrors.

The Multi-DM Family

A versatile deformable mirror system for advanced wavefront control.

The popular Multi-DM family offers sophisticated aberration compensation in an easy-to-use package. With 137 or 140 precisely controlled elements and low inter-actuator coupling, this type of system is ideal for a broad range of applications including microscopy, astronomy, retinal imaging, and laser beam shaping. Some examples include enhanced STED microscopy and MINFLUX microscopy from Abberior Instruments and the DeMi satellite mission from MIT's Star Lab which demonstrates the capabilitiy of MEMS deformable mirrors in space astronomy. Scroll down for more information on various options.

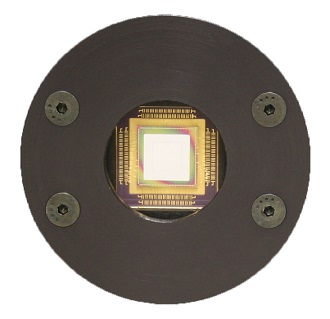

The Kilo-DM Family

The Kilo-DM Family offers enabling components for precise, high resolution wavefront control with low response time.

With up to 952 actuators controlled to under 1nm of precision with no hysteresis, this system type is ideal for demanding applications. For added speed, low-latency drive electronics are capable of 60 kHz frame rate with 14 bit step resolution.

The +K DM Family

The +K-DM Family: High spatial-resolution wavefront correctors for next generation applications in astronomy and laser communication.

The large array of underlying actuators enables extreme wavefront manipulation for specialized applications. Our +K-DM systems are found at astronomical installations around the world and enable discovery at such on-sky instruments as the Subaru Coronagraph Extreme Adpative Optics (SCExAO) instrument, the Gemini Planet Imager (GPI) and the Magellan Extreme Adaptive Optics (MagAO-X) instrument.

Continuous Deformable Mirror Standard Models

Continuous Deformable Mirror Standard Models

Multi-Driver

USB 2.0 interface

120-240 VAC input

14 bit step resolution

Maximum Frame Rate: 2 kHz

Dimensions (W × D × H): 9" x 7" x 2.5"

Kilo-Driver

DIO Interface: SFP fiber link connection via PCIe Interface Card

Form Factor: 3U Chassis (5.25" x 19" x 14")

14 bit step resolution

Maximum Frame Rate: 45 kHz

Latency†: 22 µsec

Dimensions: 5.25" x 19" 14"

X-Driver

DIO Interface: Camera Link via PCIe Interface Card

#Parallel HV Output Channels: 32 or 140

Maximum Output Voltage: 300 V

HV Interface: 37-Pin D-Sub Connector (4x)

Resolution: 14-bit

Voltage Step Size: 18mV

Latency: <2 µsec

Single Channel Update Rate: 400 kHz

Maximum Frame Rate (140 Channels): 100 kHz

External Power Supply: 24 V DC, 2A Max

Dimensions(W × D × H): 9" x 7" x 2.5"

Kilo-Low-Latency-Driver

DIO Interface: SFP fiber link connection via PCIe Interface Card

Form Factor: 3U Chassis (5.25" x 19" x 14")

14 bit step resolution

Maximum Frame Rate: 60 kHz

Latency†: 17 µsec

Dimensions: 5.25" x 19" 14"

+K Driver

DIO interface: SFP fiber link (2.5 Gbps)

120-240 VAC input

14 bit step resolution

Frame Rate: 20 kHz

Dimensions: 5.25" x 19" x 14" (3U Chassis)

Where Are Deformable Mirrors Used?

-

Astronomy

Our deformable mirrors are fielded at prominent astronomical facilities around the world to help researchers improve wavefront correction capabilities, enabling cutting edge space telescope concepts.

-

Microscopy

Our robust deformable mirrors allow users precise wavefront control in a user-friendly design, making our deformable mirrors the ideal wavefront correctors for many microscopy modalities. Click below for this general topic or click here to learn more about focus control with the Multi-DM.

-

Laser Communication

Boston Micromachines Corporation has experience providing deformable mirrors for free-space laser communication applications to a host of companies and government organizations.

-

Laser Research

In contrast to liquid crystal spatial light modulators (SLMs), MEMS deformable mirrors have recently emerged as a high-speed alternative with significant advantages. In addition, MEMS DMs are also more cost-effective, more optically efficient, and can perform simultaneously at multiple wavelengths.

-

OEM Solutions

Take our high-performance hardware to the next level by integrating deformable mirrors into your commercial application. Our systems are able to be packaged for use in fielded applications in a myriad of industries.

Boston Micromachines Corporation has the best components available to help you make your research project a reality. Unsure which deformable mirror will best suit your needs? We can help you make the optimal choice so that you can focus on moving your research forward.